You are here

With many years experience in wheel building, we can proudly say we are the most accomplished wheel builders in the BeNeLux

Our wheel building team are trained to the highest standard and have many years experience not only in assembling wheels but also in rim and spoke geometries. It is our vast experience coupled with an acute attention to detail that enables us to product wheels of the highest standard.

When it comes to rebuilding a wheel we are able to offer all the services you should require to transform that tired old hub into a shiny new wheel So why not let use take the hassle out of rebuilding your wheels, leaving you the time to look for those other elusive spares ?

We didn't invent the wheel, but we've built and restored it many thousands of times since '

Motorcycle manufacturers supply rims pre-drilled to fit the hubs and CAD drawings for the spoke design and specification. The spokes are produced to exacting tolerances and then we use pre-set jigs and tooling for accurate wheel assembly.

One-off orders are more of a challenge, as the individual requirements of each customer vary enormously, this is where the experience of the true wheel builder counts. Each one of our wheel technicians undertakes many months of training before they are trusted with our customers wheels.

The essentials

Most of our one-off orders are usually requests for wheel rebuilding, but before this can happen we need certain important measurements. These must be taken by the customer or our technicians while the old wheel is still in one piece.

The first measurement we need is the wheel's offset (or dish, as it is often called), you can see how to measure this on the "Rim Ordering Procedure" page. This measurement is essential if the rebuilt wheel is to sit correctly in the frame.

The spokes must be measured accurately, remembering that there may be more than one length of spoke in a wheel. It is also worthwhile retaining one of the old spokes for reference.

The final measurement is the size of the rim, which should be stamped on the side of the rim, e.g., 18x2.15. we have a huge database of offsets, spoke lengths and rim sizes, but these will only cater for the original fittings. Over time, many bikes will be tinkered with and improved to accommodate the latest tyres or will be fitted with incorrect spacers etc., so the above measurements are essential to ensure your wheels are correct when returned to you.

All this information means you could rebuild your wheels yourself, if you feel up to the challenge; read on and learn how to do it.

Once all the measurements have been taken, the first job is to cut the hub out of the rim using bolt cutters on the spokes and to remove the spoke ends from the hub and rim.

Most wheels have 36 or 40 spokes, some may have as many as 72 and each spoke hole has to be punched at a precise angle to ensure correct alignment between rim and hub. The hub dimensions and offset measurement are vital for this task; advice on taking these measurements can be found on the "Rim Ordering" page.

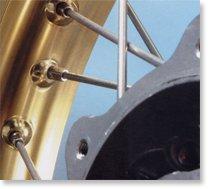

New stainless steel spokes are hooked onto the hub, a process known as lacing. Care must be taken when "lacing" the hub as inner and outer spokes may be different lengths.

Maintaining the correct spoke pattern the threaded end of each spoke is offered up to the rim and the nipples are fitted. It is important to make sure the rim is the right way round with the disc side of the rim to the disc side of the hub.

Once all the spokes are fitted in the correct position, the nipples can be tightened evenly to tension the wheel and the offset can be checked with a straight edge. The fully tensioned wheel is checked to see it is true. At this stage any radial (up and down) or axial (side to side) run out is corrected by slackening some spokes and tightening others, an operation requiring great skill and patience.

A final check of the offset is made and the wheel is examined carefully to ensure all the spoke heads are seated correctly in the hub. It is essential that no spoke ends are left protruding through the nipples as these may cause punctures if left uncorrected.

It is common to see spokes protruding through the nipple, not because the wrong spoke length has been selected, but due to different rim thicknesses, incorrect dimple spacing or even inaccuracies in the hub.

Once any protruding spokes have been ground flush with the nipple, the finished wheel is ready for the rim tape, tyre and tube. Tyre fitting is a specialist service and after the time, trouble and expense of finishing your new wheels, we would not recommend attempting this yourself and run the risk damaging them.

|

Luytenimport manufacture its own brand of LSP. spokes and Nipples. These are available in various materials and gauges and can be supplied in any quantity from 40 for one off wheels to 100,000+ for original equipment or replacement wheel suppliers. |

| The spokes currently available are:

Galvanised has long been the traditional material for spokes, but today Stainless Steel is far more popular and gives a better, longer lasting finish. Unpolished Stainless Steel spokes resemble galvanised spokes with the added benefit of being corrosion resistant. Polished Stainless Steel gives spokes a chrome-like appearance, but without the same level of maintenance. |

|

Butted Spokes are supplied in stainless or SM Pro Performance unplated steel and Double Butted are supplied in stainless steel.

LSP Performance Spokes are made from a high tensile stainless steel developed for the motocross market which is hard wearing and will not stretch with use. All galvanised spoke sets are supplied with zinc-plated steel nipples, stainless steel spoke sets with nickel plated brass nipples.

Be aware that similar materials can seize together over time, so if you would like advice on materials do please ask.

Providing the essential link between hub and rim The primary role of spokes is to give strength to the wheel, but the criss-cross effect of gleaming metal also looks visually pleasing.

| We at Luytenimport manufacture galvanised and stainless steel spokes, the latter being supplied either polished or unpolished.

The material and finish chosen for a specific job will depend on several factors - the type of bike, its age and your personal preferences. The information below will help you decide. Spokes vary greatly in length and diameter, some wheels featuring butted spokes. These aren't a uniform thickness but taper down from one diameter to another and in rare cases you'll find double butted spokes, which are thicker at each end for greater strength. |

|

Our spoke sets for a one-off wheel comprise 40 spokes with nipples, though obviously we're happy to supply any number of spokes, whether it's 10 or 100,000.

Manufacturing spokes

All our spokes are manufactured from the highest grade Stainless Steel or mid carbon galvanised steel, which ensures the optimum combination of strength and performance. Stocks of blank spokes (headed but not threaded or bent) are made and held in stock ready to be bent and cut down for our smaller orders or spoke sets. Butted spokes are made from wire which is the thickness of the butted end but are intentionally cut short. The spokes are then hammered out to length, reducing the diameter of all except the butted end. The final part of the process is to clean and polish the spokes. Large vibrating metal bowls full of polishing compound and ceramic pellets clean the spokes through abrasive action. Similar vibrating bowls containing maize apply the final polish.

Which size ?

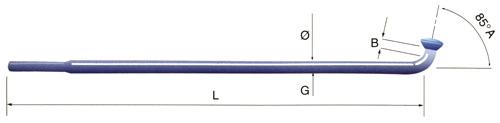

Over the years we've amassed a good knowledge of which spokes fit which bikes. Even so, it is advisable to provide a sample spoke with your order and to supply details on the length, gauge, angle and length of bend of spokes required (see diagram below).

L = Length of Spoke

A = Angle of Spoke

G = Gauge of Spoke

B = Length of Bend of Spoke

Example: 40 Spokes, L = 150mm, G = 9, A = 90 Degree, B = 12mm

When ordering butted or double butted spokes both gauges should be given. For example, if the spoke tapers from 8 to 10 gauge, write it as 8/10g.

Please note: that lengths of bend will be supplied as near to requested size as possible. It must be remembered that stainless steel does not bend as tightly as galvanised material, so not all requested bends are attainable.

Spokes supplied are replacements not replicas. Some spokes may vary in length of bend or angle from original. When assembled and tensioned these spokes will bed and sit correctly in the hub.

Standard Butted Spokes

Double Butted Spokes

Single Diameter Spokes

On this page you can find more information about how to order rims.